Customer-specific measurement and inspection tools

for professional quality control

Do you require tailor-made measuring and inspection tools in order to check the geometry and the functionality of your products? In that case, you have come to the right place. LANGER is your all-round service provider for part inspection and quality control. From the simple measuring jig to the fully automatic measuring fixture, from inspection fixtures to assembly bucks and structure bucks, we supply you with individually manufactured inspection tools for all industries. In the process, we draw on 50 years’ experience in inspection tool design and construction. Customers all around the world profit from our high quality and sustainability standards.

- Design, manufacture, assembly and measurement of the fixture on our own DAkkS-calibrated measuring machines from a single source

- High-precision inspection tools according to individual requirements

- Global delivery

Inspection tools from LANGER: Your inspection gauge manufacturer in Germany

High-quality and customer-specific: You can rely on measuring equipment from LANGER

Reliable measuring fixtures form the basis of effective quality control. Regular part inspection is essential to guarantee the consistent quality of products. To achieve this, high-precision inspection instruments tailored to the individual application are required. During inspection tool construction, our LANGER team works closely with you in order to develop the optimum and economical solution.

Customer-specific inspection fixtures: All services from a single source

With regard to quality control, LANGER is your competent partner for all phases of the project. From the first consultation to the finished product, you receive all services from a single source. With our customer-specific inspection services, we cater precisely to your needs. Through many years’ experience in a wide range of projects, we know how we can best support you with all aspects of quality control. Thanks to short decision-making paths and customer-oriented production control, we react to you needs with great flexibility.

During inspection tool and gauge construction we set great store by customer orientation. We pool all machines and qualifications required for their manufacture under one roof and offer all services in-house. Besides the automotive sector, we also work for customers in construction, medical technology, mechanical engineering and the aerospace industries. To ensure straightforward communication with our customers, we use EDI.

During inspection tool and gauge construction we set great store by customer orientation. We pool all machines and qualifications required for their manufacture under one roof and offer all services in-house. Besides the automotive sector, we also work for customers in construction, medical technology, mechanical engineering and the aerospace industries. To ensure straightforward communication with our customers, we use EDI.

Send us a non-binding request now and we will advise you!

Sales manager for inspection device

and jigs/aerospace

Dieter Stadler

+49 7558 930-611

Send E-Mail

Download VCard (.vcf)

and jigs/aerospace

Dieter Stadler

+49 7558 930-611

Send E-Mail

Download VCard (.vcf)

Top quality in inspection tool construction

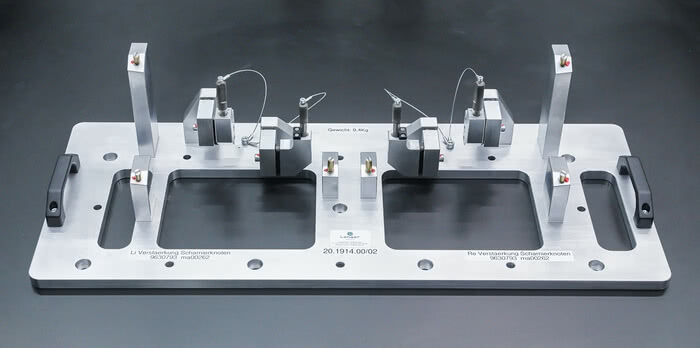

We precisely implement your wishes in the development of inspection tools. All inspection tools manufactured by LANGER precisely meet your specifications. Using our annually maintained and DAkkS-calibrated measuring machines, we guarantee the consistently high quality and dimensional accuracy of our products.

Also rely on LANGER’s experience and expertise in the following fields:

Plastic injection moulding

Tool/mould construction

Cubing model construction

Renewable energy

Also rely on LANGER’s experience and expertise in the following fields:

Plastic injection moulding

Tool/mould construction

Cubing model construction

Renewable energy

Sustainable production: Responsible inspection tool construction

LANGER sets great store by environmentally friendliness. We manufacture gauges and inspection tools in an extremely sustainable and resource-conserving manner. We reduce the amount of waste to a minimum, recycle material and offer reusable packaging for our products.

Compact overview of services

| Gauge size | Up to 6000 mm |

|---|---|

| Certificates | ISO 14001, IATF 16949, ISO 50001, ISO 9001, DIN ISO 45001, TISAX, AEO, Energy Efficiency and German Sustainability Code |

As multifaceted as your products: Inspection tool construction for every requirement

Quality control is an important and responsible task that requires precise and reliable equipment. Our range of services includes a wide variety of different inspection tools in order to support customers in all sectors during quality control. Our expertise in inspection tools and measuring instruments covers the following subfields:

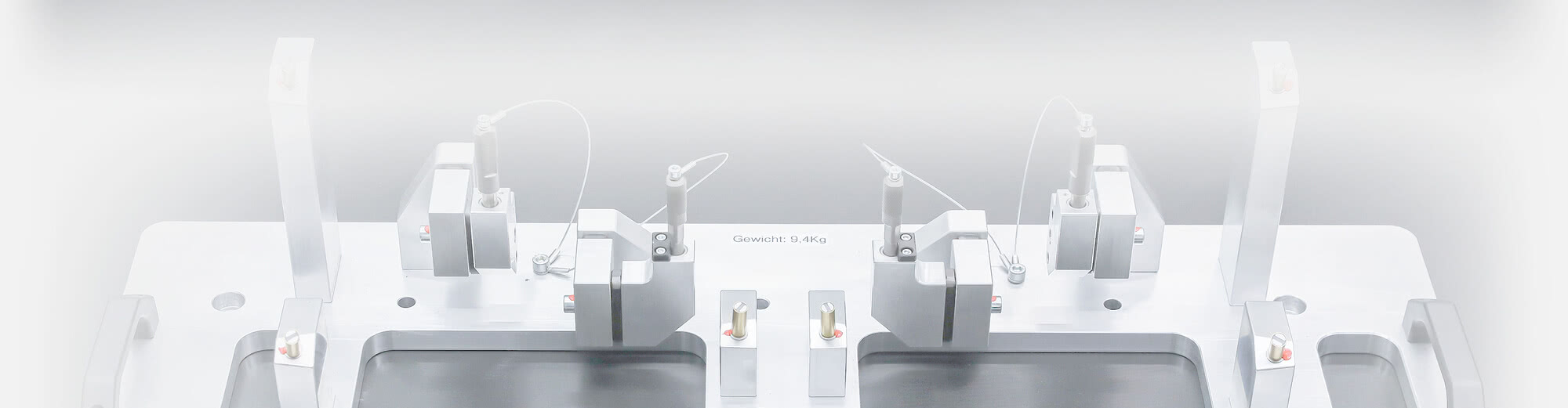

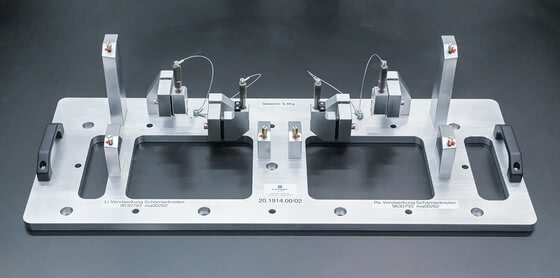

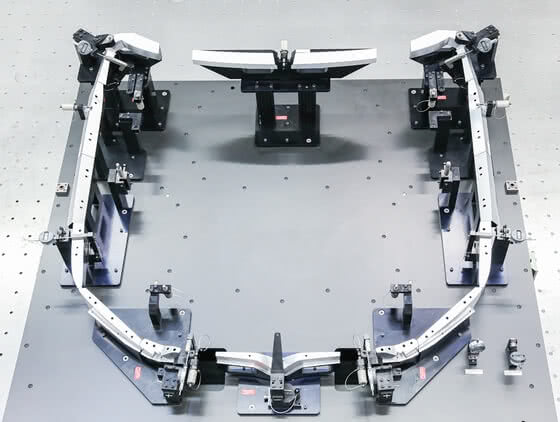

Inspection fixtures

Using inspection gauges and measuring fixtures, we determine whether parts fulfil certain requirements. Depending on the object to be measured, these types of inspection fixtures can have a wide range of different forms. Besides simple customer-specific inspection fixtures, LANGER also provides you with the following modern measuring fixtures:

- Inspection fixtures

- Measuring fixtures in connection with a coordinate measuring machine

- Fully automatic measuring fixtures with measured value transmission to CAQ software

- Mobile measuring fixtures with CFRP frame technology for low weight, high inherent rigidity and the minimum amount of thermal expansion

Our fully automatic measuring machines work with measuring probes and are designed for the measurement of defined measuring points. If required by the customer, the result is recorded via good-bad labelling including statistical evaluation. A CE marking in accordance with the EU Machinery Directive is part of our standard scope of delivery and rounds off the human-machine safety aspect.

Gauge construction

Inspection gauges are reference standards and serve to determine whether an object has a certain form or a certain dimension. The purpose of gauges is not to measure but only to check. This means that they do not provide information about numerical values, but rather only allow a comparison between the target and the actual status. LANGER offers you individually manufactured gauges for every application.

Measuring jigs

With measuring jigs or mounting fixtures, parts are fixed in place in order to measure them under controlled conditions. The clamping process must be easily reproducible. This enables series production parts to be measured quickly without compromising the measurement accuracy. From measuring jig manufacturer LANGER, you receive customer-specific measuring jigs that are precisely tailored to your needs.

Fixtures according to customer requirements

Contact us with regard to your requirements on the measurement and inspection of parts. We are always open to new applications and measuring processes. We will also be glad to support you with the development of special measuring tools and applications. Our qualified staff find the right solution for every problem.

Gauge manufacturer: Your project is in good hands with the LANGER GROUP

✔ Pre-engineering

Already during the preparation of the quotation, we contribute our huge repertoire of know-how and experience to your project.

Already during the preparation of the quotation, we contribute our huge repertoire of know-how and experience to your project.

✔ Automation

Thanks to a high degree of automation, our manufacturing processes are quick and flexible.

Thanks to a high degree of automation, our manufacturing processes are quick and flexible.

✔ Quality control

Comprehensive inspections and measurements ensure that every product meets our strict quality standards.

Comprehensive inspections and measurements ensure that every product meets our strict quality standards.

✔ Global delivery

We offer certified quality "made in Germany” and that all around the world. We would also be happy to deliver our products to your country.

We offer certified quality "made in Germany” and that all around the world. We would also be happy to deliver our products to your country.

Development of inspection tools: How is a project conducted at LANGER?

As a full-service partner, we are ready to support you during every step of your project. A single contact person will be assigned to you from the request to delivery. This is how a project is conducted at LANGER:

Consultancy/pre-engineering

Our specialists contribute their skills to your order right from the start. Qualified staff from different departments work together to find the perfect solution to cater for your needs. In this way, you profit from our wealth of experience and know-how during every phase of your project.

Design and development

We would be happy to take on responsibility for the planning, further development or the complete design of your inspection tools. We are also the ideal partner in the field of component group design. To this purpose, tell us what your measuring fixtures are required for and which properties they should have. If you already have a draft design, we would be happy to help with its further optimisation.

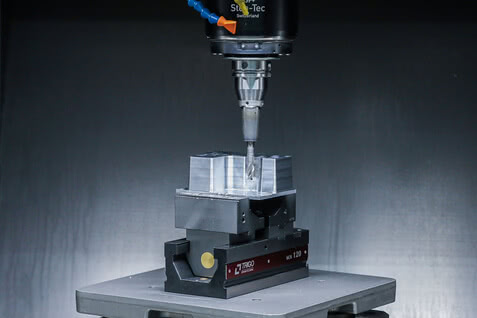

Construction of inspection tools

One of our core competencies is the economical manufacture, measurement and calibration of inspection tools. Your expectations with regard to the finished product are put into practice with absolute precision. We use state-of-the-art technology and equipment to achieve maximum efficiency and cost-effectiveness.

Quality control

When you commission LANGER to manufacture inspection tools or measuring fixtures, nothing is left to chance. After all, the key factors for these types of instrument are absolute precision and close tolerances. In our fully air-conditioned measuring rooms, we ensure that our products precisely meet your expectations using high-precision tactile measuring machines. Our measuring machines are DAkkS-calibrated, the measurement uncertainty at 3.5 cubic metres is less than 0.02 mm over to a maximum measuring range of 6,000 mm. Meticulous measurement equipment management guarantees the reliability of all control processes.

Logistics service

We deliver all around the world and are familiar with the challenges that can arise with international shipments. For this reason, we offer our customers comprehensive storage and logistics solutions including customs clearance and a transport service. In the process, we pay attention to continuous article traceability. We would be happy to enter individual agreements with regard to the spare-parts supply for our customers.

Measuring/inspection fixtures: Full service for maximum customer satisfaction

LANGER offers you measuring equipment in Southern Germany with all-round service. We consider ourselves to be not only a service provider, we would also like to provide you with comprehensive support during your project. With our broad service portfolio that goes far beyond just inspection and measurement, we are ready to help you with every stage of your work. From the idea to the finished part, we are the ideal partner for every industry and every project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency and on-time delivery are just a few examples of the qualities that distinguish us as a partner for your quality control. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency and on-time delivery are just a few examples of the qualities that distinguish us as a partner for your quality control. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Have we aroused your interest?

Arrange an appointment for a non-binding consultation now!

Sales manager for inspection device

and jigs/aerospace

Dieter Stadler

+49 7558 930-611

Send E-Mail

Download VCard (.vcf)

Arrange an appointment for a non-binding consultation now!

Sales manager for inspection device

and jigs/aerospace

Dieter Stadler

+49 7558 930-611

Send E-Mail

Download VCard (.vcf)