Prototype construction: Custom prototype injection-molding tools

LANGER is your competent partner with all-round service for prototype tool construction. Customers from all industrial sectors profit from our services in customer-specific prototype development. We manufacture prototype tools in a wide range of shapes and sizes and find the ideal solution for every order.

Use our high-quality aluminium molds among others for the following applications:

Use our high-quality aluminium molds among others for the following applications:

- Injection-compression molding

- MuCell® (physical foaming) / chemical foaming

- Integration of heating duct systems

- Internal gas-assisted injection molding

- Extrusion blow molding / plastic housing

- Two-component injection molding

- Molding around inserts

Prototyping technology: LANGER at a glance

During prototype development, we draw on 51 years’ experience gained during our company's history. We ensure the consistently high quality of our prototype parts using computer tomography, laser scanning as well as optical and tactile measurement. We deliver to customers all around the world and pay heed to a resource-conserving and sustainable way of working during the prototype construction.

Prototype injection molds: Working together with us, you go into series production faster

Ideas for plastic injection-molded parts are rarely ready for series production right from the start. Over the course of the development, draft designs must be optimised and change requests taken into account. Prototypes are indispensable for this process. They provide insights into the part, for example regarding its strength and surface finish. To do this, prototype injection-molding tools close to the series production level are required that are precisely adapted to suit the requirements of the product development.

We at LANGER specialise in the creation of prototype tools. From simple to highly complex prototype molds, we provide you with tailor-made prototype tools. Our competencies also include the manufacture and assembly of component groups. Our prototype molds enable cost-saving and reliable manufacturing of prototypes so that your product can go into series production as quickly as possible.

We at LANGER specialise in the creation of prototype tools. From simple to highly complex prototype molds, we provide you with tailor-made prototype tools. Our competencies also include the manufacture and assembly of component groups. Our prototype molds enable cost-saving and reliable manufacturing of prototypes so that your product can go into series production as quickly as possible.

Send us a non-binding request now and we will advise you!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Prototype model construction: Flexible manufacturing from a single source

Product development is a dynamic process, meaning that flexibility is particularly important during the manufacture of prototype tools. For this reason, LANGER offers short decision-making paths, customer-oriented production control, 24-hour production and express service. Numerous satisfied customers bear witness to our high degree of customer orientation. Among others, we receive orders for prototype construction from the automotive, construction, medical technology, mechanical engineering and aerospace industries.

From consultancy to quality control, you receive all services from a single source. In the process, the communication via EDI enables simple and flexible data exchange with our customers.

From consultancy to quality control, you receive all services from a single source. In the process, the communication via EDI enables simple and flexible data exchange with our customers.

Customers in the following fields also profit from our high quality standards:

Plastic injection molding

Cubing model construction

Inspection tool and gauge manufacturing

Renewable energy

Plastic injection molding

Cubing model construction

Inspection tool and gauge manufacturing

Renewable energy

Uncompromising quality and comprehensive service in prototype construction

We implement your wishes precisely when manufacturing prototypes. From the grain to the thickness to the runner, our series production molds for small batches correspond exactly to your specifications. Engravings are also no problem at all.

State-of-the-art quality control measures and experienced staff ensure the consistently high quality of our products.

Our all-round service includes bespoke packaging, an international transport service as well as storage of components.

State-of-the-art quality control measures and experienced staff ensure the consistently high quality of our products.

Our all-round service includes bespoke packaging, an international transport service as well as storage of components.

Exemplary sustainability: Plastic prototype construction with responsibility

We set great store by environmentally friendliness during all process steps. Our prototype construction is extremely sustainable and resource-conserving. We minimise the amount of waste material and recycle to a very large extent. Furthermore, we offer reusable packaging for finished products.

Compact overview of services

| Compatible materials | Polypropylene (PP, PP-GF), thermoplastic elastomers (TPE), polyamides (PA, PA-GF), plastics with and without filler materials. In addition, we also support you by running trials with new test materials. |

|---|---|

| Mold size | 196 x 196 mm to 1396 x 1396 mm |

| Tool weight | Up to 10 t |

| Closing force | 50 t to 1700 t |

| Tools | Two-component tools, family tools, tools for different part variants, tools for low-volume production, high-temperature tools up to 160 °C, hybrid tools |

| Manufacturing technologies | Two-component manufacturing, internal gas-assisted technology, molding around inserts, valve gate technology, rotary slider technology |

| Assembly work | Ultrasonic welding of plastics, vibration welding of plastics, component group assembly, rework of injection-molded parts by machine |

| Certificates | ISO 14001, IATF 16949, ISO 50001, ISO 9001, DIN ISO 45001, TISAX, AEO, Energy Efficiency and German Sustainability Code |

Advantages of plastic injection-molded prototypes at a glance

Prototype parts made of plastic are an important building block in the development chain of new products. Nowadays, it is impossible to imagine modern industry without injection-molding prototype construction. Use our prototype injection-molding tools that are close to series production level and profit from the following advantages:

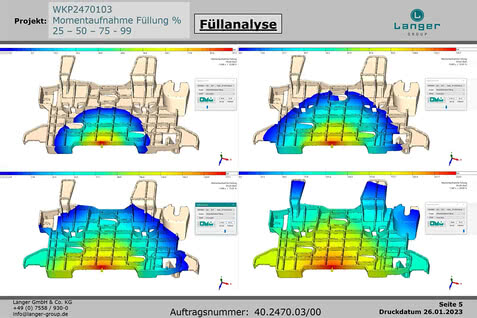

Product development

Plastic prototype parts allow a detailed evaluation of the current development status. Step by step, it becomes clear how the required series production tools need to look. Investigate, for example, the filling, shrinkage and deformation behaviour or the durability of the prototype and drive the development forwards with these insights.

Flexibility

Injection-molded prototypes are thus a very flexible and time-saving way of checking the current development status of a product. In the process, the tool materials used can generally be machined more easily and thus more quickly and cheaply than during the later manufacture of the series production tool. This allows a dynamic way of working, and that is precisely the advantage of rapid prototyping.

Avoiding costs

If errors or potential for improvement are discovered during series production, this costs time and money. High-quality prototypes help avoid this. Our tools enable economical one-off and small-batch production of prototypes in order to develop the perfect product step by step.

Your project is in good hands with the LANGER GROUP

✔ Pre-engineering

Before the actual manufacturing, we contribute our huge repertoire of know-how and experience to your project.

Before the actual manufacturing, we contribute our huge repertoire of know-how and experience to your project.

✔ Virtual simulation

We avoid rejects and waste material and save time and costs by digitally testing the injection process beforehand.

We avoid rejects and waste material and save time and costs by digitally testing the injection process beforehand.

✔ Automation

Thanks to a high degree of automation, we manufacture high-quality parts in large quantities on a daily basis.

Thanks to a high degree of automation, we manufacture high-quality parts in large quantities on a daily basis.

✔ Global delivery

We offer quality "made in Germany” and that all around the world. We would also be happy to deliver plastic injection-molded parts to your country.

We offer quality "made in Germany” and that all around the world. We would also be happy to deliver plastic injection-molded parts to your country.

Aluminium tools: How is a project conducted at LANGER?

As a full-service partner, we are ready to support you during every step of your project. A qualified contact person is available to help you at all times. This is how a project is conducted at LANGER:

Consultancy/pre-engineering

Our specialists contribute their skills to your order right from the start. Qualified staff from different departments work together to find the perfect solution to cater for your needs. In this way, you profit from our wealth of experience and know-how during every phase of your project.

Design and development

We assume responsibility for the complete planning and design of your tools. Tell us what your prototypes are required for and which properties they should have. If you already have a draft design, we would be happy to help with its further optimisation.

Prototype tool construction

One of our core competencies is the manufacture of high-quality prototype tools. Your expectations with regard to the finished product are put into practice with absolute precision. We use state-of-the-art technology and equipment to achieve maximum efficiency and cost-effectiveness.

Quality control

When you commission LANGER to manufacture prototype molds, nothing is left to chance. After all, the key factors for the creation of prototypes are absolute precision and close tolerances. Our in-house quality control includes computer tomography, laser scanning, optical and tactile measurement, 3D measurement, 3D coordinate measurement as well as initial sample test reports. The evaluation is carried out using the software Polyworks. We create measurement reports according to the drawing or the measuring plan. Meticulous measurement equipment management guarantees the reliability of all control processes.

Logistics service

We deliver all around the world and are familiar with the challenges that can arise with international shipments. For this reason, we offer our customers comprehensive storage and logistics solutions including customs clearance and a transport service. In the process, we pay attention to continuous article traceability. We would be happy to enter individual agreements with regard to our customers’ post-series and spare-parts supply.

Prototype injection molding:

Flexible prototype tool construction for ever requirement

We offer customers in all industries comprehensive services regarding all aspects of prototype design and construction. Automotive prototyping is one of the fields most often requested. Prototype construction for the automobile sector is one of the most important stepping stones on the way to the development and improvement of vehicles. Prototype vehicle parts not only reveal potential for optimisation with regard to function and safety, but are also essential for the development of the design.

The following are some examples from our prototype service portfolio that we can provide on our injection-molding machines:

The following are some examples from our prototype service portfolio that we can provide on our injection-molding machines:

- Cable ducts

- Cable brackets

- Air dusts

- Covers

- Brackets

- Panels

- Structural components

- Intake manifolds

- Cylinder head covers

- Housings for thermal control units

- Dehumidifiers

- Air filters

- Expansion tanks

- Molding around inserts (bushings, strainers, fleece, fabric)

- Filter housings

- Air flap systems

- Cylinder head covers

- Engine compartment parts

- Small fixtures in general

- Air ducts

- Tank housings

Prototype injection-molding tools "made in Germany": Full service for maximum customer satisfaction

LANGER is your mold construction specialist with all-round service. We consider ourselves to be not only a service provider, we would also like to provide you with comprehensive support during your project. With our broad service portfolio, we are ready to help you with every stage of your work. From the idea to the finished tool, we are the ideal partner for every industry and every project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency and on-time delivery are just a few examples of the qualities that distinguish us as a tool manufacturer. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency and on-time delivery are just a few examples of the qualities that distinguish us as a tool manufacturer. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Have we aroused your interest?

Arrange an appointment for a non-binding consultation now!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Arrange an appointment for a non-binding consultation now!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)