Plastic injection moulding for defence technology

Precision and reliability for demanding missions

Compromises are not an option in defence technology. Every part and every component must function reliably under the most extreme conditions and meet the highest safety standards. LANGER is your experienced partner for high-precision and extremely robust plastic components that are specially developed and manufactured for the critical requirements of the defence and security industry. You can rely on our in-depth expertise and solution-orientated approach to successfully implement your complex projects.

High-performance plastics for defence & security

Why plastic injection moulding is indispensable in defence technology

Modern defence technology places the highest demands on materials and production. High-performance plastics, manufactured precisely by injection moulding, offer decisive advantages over traditional materials:

- Weight saving & mobility: Lightweight plastic components reduce the overall weight of equipment and systems - a critical factor for mobility, range and transport capacity in military applications.

- Extreme resistance: Our specially selected polymers withstand extreme temperatures, aggressive chemicals, UV radiation, vibrations and shocks. They therefore guarantee unrestricted functionality under the toughest operating conditions.

- Corrosion resistance & durability: Unlike metals, plastics are immune to corrosion. This significantly extends the service life of components and minimises maintenance costs - essential for reliability in the field.

- Design freedom & function integration: The plastic injection moulding process enables the realisation of complex geometries and the integration of several functions in one component. This reduces assembly work, the number of components and therefore costs.

- Specific electrical properties: From precise electrical insulation to effective electromagnetic shielding (EMI/RFI), plastics offer a wide range of options for optimising electronic systems in defence technology.

- Vibration damping & noise reduction: By using suitable polymers, we can develop components that dampen vibrations and reduce noise, which improves the ergonomics and camouflage capability of systems.

- Cost efficiency: Particularly in series production, plastic injection moulding offers an economical alternative to other manufacturing processes without compromising on performance or reliability.

Our expertise for your requirements - make a non-binding enquiry now!

LANGER combines comprehensive material expertise with excellent toolmaking and high-precision manufacturing. This symbiosis makes us the ideal partner for demanding defence technology projects.

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Managing Director

Head of injection molding department

Markus Beierl

+49 7558 930-604

Send E-Mail

Download VCard (.vcf)

Head of injection molding department

Markus Beierl

+49 7558 930-604

Send E-Mail

Download VCard (.vcf)

Material expertise for the highest demands

Choosing the right material is crucial for the performance of the end product. We provide comprehensive advice on the selection and processing of high-performance polymers and special engineering plastics. Our in-depth knowledge covers a wide range of properties: from extreme impact resistance and flame retardancy to radar transparency/absorption and ESD protection. Together we will find the optimum material solution that exactly matches your specifications and application conditions.

High-performance polymers for extreme requirements in defence technology

These plastics are the first choice when it comes to maximum load-bearing capacity, thermal stability and chemical resistance.

| Material | Properties | Preferred areas of application |

|---|---|---|

PEEK (Polyetheretherketon) | Excellent mechanical strength and rigidity, high continuous operating temperature (up to approx. 250°C), outstanding chemical resistance, low water absorption, good sliding and wear properties, radiation resistant. | Precision parts in optics and sensor technology, bearings, bushings, gear components, mountings for electronics, parts for unmanned systems, safety-critical applications. |

PPS (Polyphenylensulfid) | High rigidity and hardness, very good dimensional stability, excellent chemical resistance (especially to aggressive media), high heat resistance, intrinsically flame retardant. | Housings for electronic components, fuel systems, parts in contact with media, components for drones and unmanned systems, components in areas exposed to chemicals. |

PEI (Polyetherimid) | High heat resistance, good mechanical properties even at elevated temperatures, high dielectric constant, good hydrolysis resistance, transparent (amorphous types), inherently flame retardant. | Insulated housings for electrical/electronic components, connectors, lighting components, components with electrical insulation and transparency requirements (e.g. viewing windows). |

PSU (Polysulfon) | High transparency (amorphous types), good mechanical properties, high heat resistance, hydrolysis resistance, good dimensional stability. | Components for optical devices, glazing, connectors and housings with transparency and heat resistance requirements. |

LCP (Flüssigkristallpolymer) | Liquid crystalline polymers – extremely high dimensional stability, very low thermal expansion coefficient, excellent flow properties for thin-walled parts, high strength and stiffness, low moisture absorption, inherently flame retardant. | Micro injection moulded parts, connectors, coil bodies, housings for miniature electronics, precision parts for small and complex assemblies, applications requiring extreme miniaturisation. |

Special polyamides and elastomers for functional components

These materials complement the high-performance polymers where robustness, damping or specific mechanical properties are required.

| Material | Properties | Preferred areas of application |

|---|---|---|

PA (polyamide) reinforced (e.g. PA6 GF30, PA66 CF30) | Glass fibre (GF) or carbon fibre (CF) reinforced polyamides offer increased strength, rigidity and temperature resistance. Good impact strength, chemical resistance, often good wear properties. | Structural components, housings, levers, handles, brackets, covers for vehicles and equipment, components with high mechanical stress and impact resistance, parts that require a high strength-to-weight ratio. |

TPU (thermoplastic polyurethane) | High elasticity and flexibility, very good abrasion and wear resistance, high tear resistance, good resistance to oils, greases and many chemicals, good damping properties, wide temperature range. | Seals, bumpers, vibration dampers, cable sheathing, flexible protective caps, handles and controls, components with elasticity and robustness requirements, noise reduction elements, parts in tactical equipment that must offer flexibility and protection. |

Special polyamides (e.g. PA11, PA12) | Low water absorption, good dimensional stability, high impact strength, good chemical resistance, more flexible than PA6/PA66. Particularly suitable for applications requiring low moisture absorption and good resistance to stress cracking. | Fuel lines, hydraulic components, pneumatic systems, housings for sensors, flexible lines and hoses, components in contact with media or in environments with moisture, where dimensional stability is critical. |

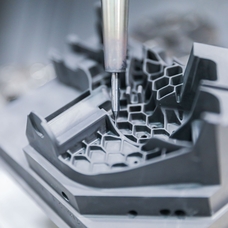

Precision in detail: from toolmaking to series parts

Our core competence lies in the development and production of injection moulds that are designed for maximum precision and reproducibility. This is the basis for plastic components that fulfil even the tightest tolerances - essential for critical functional components in defence technology. We guarantee consistent, top quality throughout the entire series, from prototype to mass production, thanks to our modern manufacturing processes and stringent testing procedures.

Our tolerance management is particularly noteworthy: we understand the importance of tight shape and position tolerances and use the latest manufacturing and measuring technologies to ensure that these are consistently adhered to. Our in-house toolmaking department guarantees the precision and durability of your components and also enables rapid iterations and adjustments during the development phase.

Our tolerance management is particularly noteworthy: we understand the importance of tight shape and position tolerances and use the latest manufacturing and measuring technologies to ensure that these are consistently adhered to. Our in-house toolmaking department guarantees the precision and durability of your components and also enables rapid iterations and adjustments during the development phase.

✔ Pre-engineering

Already during the preparation of the quotation, we contribute our huge repertoire of know-how and experience to your project.

Already during the preparation of the quotation, we contribute our huge repertoire of know-how and experience to your project.

✔ Automation

Thanks to a high degree of automation, our manufacturing processes are quick and flexible.

Thanks to a high degree of automation, our manufacturing processes are quick and flexible.

✔ Quality control

Comprehensive inspections and measurements ensure that every product meets our strict quality standards.

Comprehensive inspections and measurements ensure that every product meets our strict quality standards.

✔ Global delivery

We offer certified quality "made in Germany” and that all around the world. We would also be happy to deliver our products to your country.

We offer certified quality "made in Germany” and that all around the world. We would also be happy to deliver our products to your country.

Quality and safety as a foundation

For us, quality is not just a buzzword, but a philosophy we live by. Our certified quality management in accordance with ISO 9001 is the standard for all our processes. We understand the unique and often safety-critical requirements of defence technology and always act with the utmost care and traceability. Although we cannot provide direct references from the defence industry, our understanding of industry-specific standards such as AS9100 and other military standards is firmly embedded in our quality processes. Absolute confidentiality and discretion of your projects are a matter of course for us.

We use state-of-the-art measuring equipment and processes, including 3D coordinate measuring machines and optical measuring systems, to verify the quality of each component. We also guarantee complete traceability along the entire supply chain and at every stage of production - an absolute must for safety-relevant applications.

We use state-of-the-art measuring equipment and processes, including 3D coordinate measuring machines and optical measuring systems, to verify the quality of each component. We also guarantee complete traceability along the entire supply chain and at every stage of production - an absolute must for safety-relevant applications.

Typical applications for plastic parts in defence technology

Our precision plastic parts are used in many areas of the defence and security industry:

Housing and covers

Robust and weather-resistant housings for sensitive electronics, optronics and sensor technology, e.g. in communication devices, night vision devices or thermal imaging cameras.

Unmanned systems

Lightweight and stable components for drones, robots and autonomous vehicles that operate under harsh conditions and have to withstand extreme loads.

Vehicle/aircraft interior

Robust, flame-retardant and weight-saving panelling, brackets and control elements for military vehicles and aircraft.

Protective components

Special sealing elements, vibration dampers or impact protection made of plastics that protect critical systems.

Optical mounts

Precisely manufactured mounts and frames for lenses and optical systems that must remain stable under vibrations and temperature fluctuations.

Your special requirement?

Do you have a technical problem that needs to be solved with plastics or are you looking for an innovative alternative material? Do not hesitate.

Let's talk about your individual project!

Let's talk about your individual project!

Our comprehensive service

Your advantage as a development partner

At LANGER, you get more than just a component. We are your strategic partner who accompanies you from the initial idea through to series production.

Co-engineering and development partnership

Take advantage of our expertise right from the conception phase. We actively support you in co-engineering, optimise designs for injection moulding production and carry out detailed feasibility studies. With advanced simulation tools such as FEA (finite element analysis) and Moldflow simulation, we can predict material behaviour and manufacturing processes, minimise risks and optimise component performance. Our rapid prototyping and sampling enable early validation and significantly accelerate your development cycles, while we always keep an eye on the requirements for subsequent series production.

Efficient plastic injection moulding production and logistics

With our modern machinery, we are able to produce both small series for prototypes and pre-series as well as large series efficiently and on time. We offer reliable supply chains and flexible logistical solutions that are customised to your project phases. On request, we can also undertake precise post-processing (e.g. machining, laser labelling, printing), the assembly of complex modules (including overmoulding of metal inserts or electronic components) and the production of multi-component parts in order to offer you a complete solution from a single source.

Why LANGER is your ideal partner: trust, innovation, solution-orientation

We know that choosing a partner in defence technology is based on trust and proven expertise. LANGER stands for:

Solution-oriented thinking

We take on the unique technical challenges of your industry and develop customised, innovative solutions that not only meet your requirements, but exceed them.

We take on the unique technical challenges of your industry and develop customised, innovative solutions that not only meet your requirements, but exceed them.

Innovation and expertise

Our continuous commitment to the research and development of new materials and manufacturing processes ensures that you always have access to the most advanced solutions and latest technologies in plastic injection moulding.

Our continuous commitment to the research and development of new materials and manufacturing processes ensures that you always have access to the most advanced solutions and latest technologies in plastic injection moulding.

Trust and discretion

We treat all project information with the utmost confidentiality and offer you a secure and discreet development process that fulfils your sensitive requirements.

We treat all project information with the utmost confidentiality and offer you a secure and discreet development process that fulfils your sensitive requirements.

Quality "Made in Germany" in the heart of Europe - As a German company with production here at our site, we guarantee you the highest production quality, short delivery routes and reliable co-operation in accordance with European standards.

FAQ about plastic injection moulding in defence technology

Which plastics are particularly suitable for military applications and why?

High performance polymers such as PEEK, PPS, PEI, PSU, LCP, glass or carbon fibre reinforced polyamides and special TPU grades are suitable for military applications. These materials offer properties such as high impact resistance, extreme temperature resistance, inherent flame retardancy, excellent corrosion resistance and often the possibility of EMI/RFI shielding, which are essential for robustness and reliability in defence technology.

How does LANGER guarantee the precision and reliability of plastic components for critical applications?

We attach great importance to maximum precision in our own mould construction and production. By using state-of-the-art injection moulding machines, optical measuring methods and strict quality management in accordance with ISO 9001, we ensure that every component complies with the tightest tolerances and is absolutely reproducible throughout the entire series. Our understanding of processes and our experience are focussed on safety-critical areas.

Can plastic injection moulded parts contribute to weight savings in defence technology and what effect does this have?

Yes, significantly. High-performance plastics are much lighter than metals and still offer excellent mechanical properties. This enables considerable weight savings in equipment, systems and vehicles, which has a positive impact on mobility, range, transport capacity and ergonomics for personnel.

How does LANGER handle sensitive and secret project data from defence technology?

Absolute discretion and confidentiality are a matter of course for us and a fundamental prerequisite for collaboration in defence technology. We implement strict internal security protocols and are always ready to sign comprehensive confidentiality agreements to fully protect your sensitive project data.

What role does the choice of material play in resistance to extreme environmental influences?

The right choice of material is crucial for resistance to extreme environmental influences such as high/low temperatures, UV radiation, moisture, chemicals and vibrations. We provide you with comprehensive advice and select materials that are optimally adapted to the specific operating conditions and the required standards of your application to ensure durability and functional reliability.

Does LANGER also offer support in the development and prototyping of defence technology components?

Yes, we see ourselves as a fully-fledged development partner. We support you from the initial idea through design optimisation, material selection and feasibility studies to rapid prototyping and sampling. Our co-engineering approach and the use of simulation tools help you to accelerate your product development efficiently and with low risk.

Your project is our mission: get in touch with us!

Are you looking for an experienced and reliable partner for sophisticated plastic injection moulding in defence technology? Talk to our experts. We are ready to understand the challenges of your specific project and develop a customised solution.

Have we aroused your interest?

Arrange an appointment for a non-binding consultation now!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Arrange an appointment for a non-binding consultation now!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)