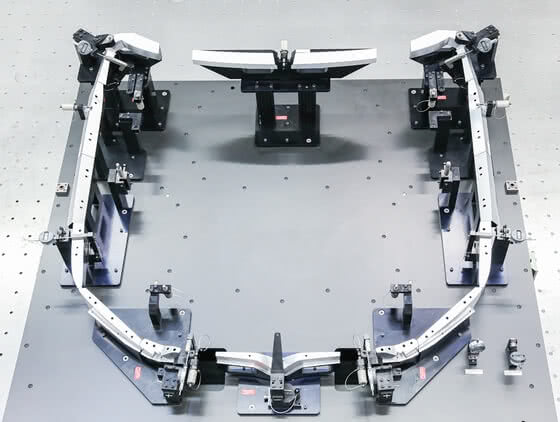

Customer-specific outer-skin/structure bucks

for individual inspection and measuring tasks

LANGER is your competent partner for the manufacture of customer-specific inspection and measuring equipment. As an all-round service provider, we support you with comprehensive services for every aspect of component inspection and quality control. Our portfolio ranges from outer-skin bucks to complex structure bucks. In the process, we draw on 51 years’ experience gained during our company's history. Customers all around the world profit from our high quality and sustainability standards.

- Design, manufacture, assembly and measurement on our own DAkkS-calibrated measuring machines from a single source

- High-precision structure and outer-skin bucks according to individual requirements

- Global delivery

Quality control in the automobile industry: LANGER at a glance

High-quality and customer-specific: You can rely on measuring equipment from LANGER

Reliable measuring methods form the basis of effective quality control. Painstaking inspection of parts is essential in order to guarantee their quality. To achieve this, high-precision inspection instruments tailored to the individual application are required. For the quality control, we work closely with our customers in order to develop the optimum solution to meet the requirements.

Send us a non-binding request now and we will advise you!

Sales manager for inspection device

and jigs/aerospace

Dieter Stadler

+49 7558 930-611

Send E-Mail

Download VCard (.vcf)

and jigs/aerospace

Dieter Stadler

+49 7558 930-611

Send E-Mail

Download VCard (.vcf)

Customer-specific inspection fixtures: Flexible manufacturing from a single source

From the idea to the finished product, you receive all services from a single source. Profit during your project from our comprehensive services and our 51 years’ experience gained during our company's history. Short decision-making paths and customer-oriented production control make us an extremely flexible partner in your quality control.

Numerous satisfied customers bear witness to our high degree of customer orientation in the manufacture of measuring jigs, inspection tools and bodywork gauges. Besides the automotive sector, we also work for customers in construction, medical technology, mechanical engineering and the aerospace industries. We offer all services in-house from consultancy to final quality control. In the process, the communication via EDI enables simple and flexible data exchange with our customers.

Numerous satisfied customers bear witness to our high degree of customer orientation in the manufacture of measuring jigs, inspection tools and bodywork gauges. Besides the automotive sector, we also work for customers in construction, medical technology, mechanical engineering and the aerospace industries. We offer all services in-house from consultancy to final quality control. In the process, the communication via EDI enables simple and flexible data exchange with our customers.

Uncompromising quality in inspection tool construction

We precisely implement your wishes regarding the development of gauges, measuring jigs, outer-skin and assembly bucks, and other fixtures. Our inspection tools precisely meet your specifications. The in-house quality control guarantees the consistently high quality and precision of our products.

Also rely on LANGER’s experience and expertise in the following fields:

Also rely on LANGER’s experience and expertise in the following fields:

Exemplary sustainability: Development and manufacturing with responsibility

We set great store by environmentally friendliness during all process steps. We manufacture bodywork gauges and other inspection tools in an extremely sustainable and resource-conserving manner.

Compact overview of services

| Gauge size | Up to 6000 mm |

|---|---|

| Certificates | ISO 14001, IATF 16949, ISO 50001, ISO 9001, DIN ISO 45001, TISAX, AEO, Energy Efficiency and German Sustainability Code |

As multifaceted as your parts: Inspection tool development for every application

Quality control in the automobile industry is an important and responsible task that requires precise and reliable equipment. Our range of services includes a wide variety of different inspection and measuring fixtures in order to support customers in the automotive sector during quality control. The following fixtures and instruments are relevant for measurement, inspection and control:

Outer-skin bucks, structure bucks

In the automobile industry, bucks are essential in order to fix parts in place and join them together. For example, they take up parts that are visible from the outside in order to evaluate their interplay taking clearances into account. Or they enable welded subassemblies to be joined free of tension. LANGER manufactures custom bucks according to your wishes for high-quality results in automobile development .

Fixtures according to customer requirements

Contact us with regard to your requirements on the measurement and inspection of parts! We are always open to new applications and measuring processes. We will also be glad to support you with the development of special measuring tools and applications. Our qualified team will find the right solution for every problem.

Your project is in good hands with the LANGER GROUP

✔ Pre-engineering

Already during the preparation of the quotation, we contribute our huge repertoire of know-how and experience to your project.

Already during the preparation of the quotation, we contribute our huge repertoire of know-how and experience to your project.

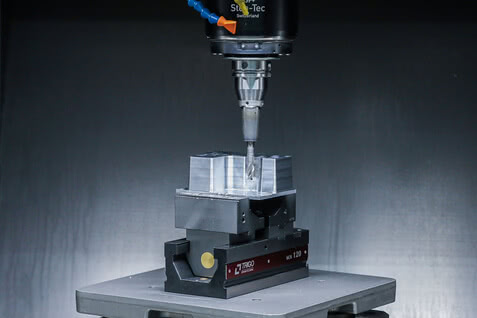

✔ Automation

Thanks to a high degree of automation, our manufacturing processes are quick and flexible.

Thanks to a high degree of automation, our manufacturing processes are quick and flexible.

✔ Quality control

Comprehensive inspections and measurements ensure that every product meets our strict quality standards.

Comprehensive inspections and measurements ensure that every product meets our strict quality standards.

✔ Global delivery

We offer certified quality "made in Germany” and that all around the world. We would also be happy to deliver our products to your country.

We offer certified quality "made in Germany” and that all around the world. We would also be happy to deliver our products to your country.

How is a project conducted at LANGER?

As a full-service partner, we are ready to support you during every step of your project. A single contact person will be assigned to you from the request to delivery. This is how a project is conducted at LANGER:

Consultancy/pre-engineering

Our specialists contribute their skills to your order right from the start. Qualified staff from different departments work together to find the perfect solution to cater for your needs. In this way, you profit from our wealth of experience and know-how during every phase of your project.

Design and development

We would be happy to take on responsibility for the planning, further development or the complete design of your inspection fixtures. Provide us with a description of your measurement needs, what you consider to be important and what specific factors need to be observed. If you already have a draft design, we would be happy to help with its further optimisation.

Production

One of our core competencies is the economical manufacture of inspection and measuring systems. Your expectations with regard to the finished product are put into practice with absolute precision. We use state-of-the-art technology and equipment to achieve maximum efficiency and cost-effectiveness.

Quality control

When you commission LANGER to manufacturer inspection fixtures for the automotive industry, nothing is left to chance. After all, the key factors for these types of instrument are absolute precision and close tolerances. In our fully air-conditioned measuring rooms, we ensure that our products precisely meet your expectations using high-precision tactile measuring machines. Our measuring machines are DAkkS-calibrated, the measurement uncertainty at 3.5 cubic metres is less than 0.02 mm over to a maximum measuring range of 6,000 mm. Painstaking annual maintenance and calibration of the measuring machine guarantees the reliability of the control process.

Logistics service

We deliver all around the world and are familiar with the challenges that can arise with international shipments. For this reason, we offer our customers comprehensive storage and logistics solutions including customs clearance and a transport service. In the process, we pay attention to continuous article traceability. We would be happy to enter individual agreements with regard to the spare-parts supply for our customers.

Quality control for the automotive sector:

Full service for maximum customer satisfaction

LANGER offers you quality control with all-round service. We consider ourselves to be not only a service provider, we would also like to provide you with comprehensive support during your project. With our broad service portfolio that goes far beyond just inspection and measurement, we are ready to help you with every stage of your work. From the idea to the finished part, we are the ideal partner for every industry and every project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency and on-time delivery are just a few examples of the qualities that distinguish us as a partner for your quality control. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency and on-time delivery are just a few examples of the qualities that distinguish us as a partner for your quality control. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Have we aroused your interest?

Arrange an appointment for a non-binding consultation now!

Sales manager for inspection device

and jigs/aerospace

Dieter Stadler

+49 7558 930-611

Send E-Mail

Download VCard (.vcf)

Arrange an appointment for a non-binding consultation now!

Sales manager for inspection device

and jigs/aerospace

Dieter Stadler

+49 7558 930-611

Send E-Mail

Download VCard (.vcf)