Customer-specific tool designs: High-tech and know-how for your tools

Do you want to manufacture injection-molded parts made of plastic and require a competent partner for the design of the corresponding tools? Or would you like to optimise and further develop an existing preliminary design? LANGER offers top quality and all-round service in the design and manufacture of custom injection molds. We develop injection-molding tools among other things for the following applications:

- Injection-compression molding

- MuCell® / chemical foaming

- Internal gas-assisted injection molding

- Extrusion blow molding / plastic housing

- Two-component injection molding

- Molding around inserts

Tool design: LANGER at a glance

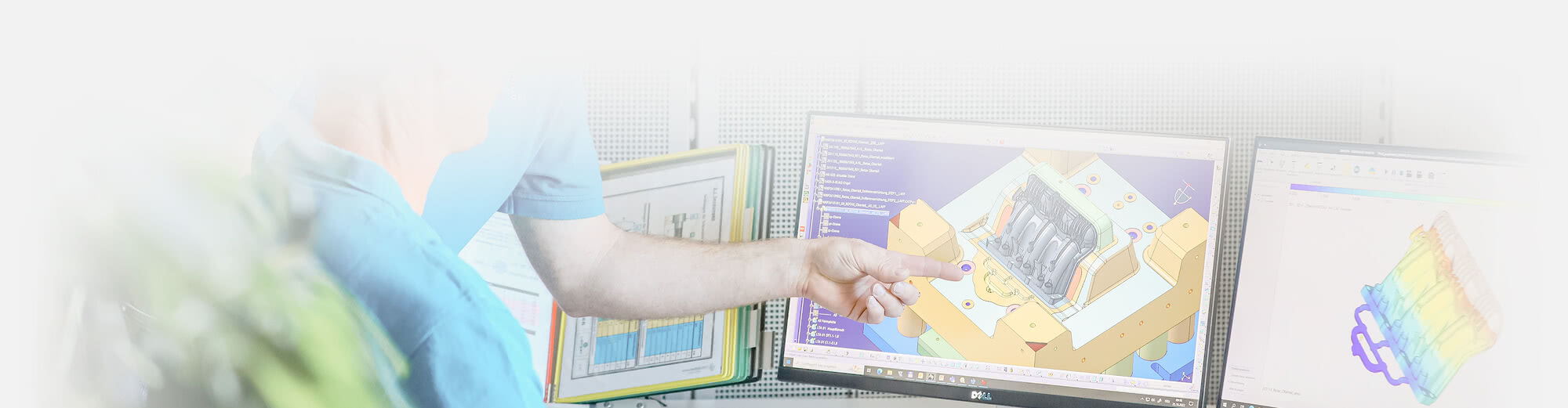

During the design of plastic injection-molding tools, we draw on 51 years’ experience gained during our company's history. We offer CAD part and tool design on the basis of CATIA as well as CAM programming (NGC CAM solution). We ensure the consistently high quality of our products using, among other methods, computer tomography, laser scanning as well as optical and tactile measurement, and we can also offer a reverse engineering service. We deliver to customers all around the world and pay heed to a resource-conserving and sustainable way of working during mold construction.

3D tool design for every industry and every requirement

We assume responsibility for the complete planning and design of your injection-molding tools. Tell us what your injection-molding tools are required for and which properties they should have. If you already have a draft design, we would be happy to help with its further optimisation. We offer CAD part and tool design on the basis of CATIA as well as CAM programming (NGC CAM solution). Our service portfolio also includes the optimisation of your component data to suit the tool.

Numerous satisfied customers bear witness to our high degree of customer orientation. Among others, we receive orders for plastic-injection molds from customers in the automotive, construction, medical technology, mechanical engineering and aerospace sectors. From consultancy to quality control, you receive all services from a single source. In the process, the communication via EDI enables simple and flexible data exchange with our customers.

Numerous satisfied customers bear witness to our high degree of customer orientation. Among others, we receive orders for plastic-injection molds from customers in the automotive, construction, medical technology, mechanical engineering and aerospace sectors. From consultancy to quality control, you receive all services from a single source. In the process, the communication via EDI enables simple and flexible data exchange with our customers.

Customers in the following fields also profit from our high quality standards:

Plastic injection molding

Cubing model construction

Inspection tool and gauge manufacturing

Renewable energy

Plastic injection molding

Cubing model construction

Inspection tool and gauge manufacturing

Renewable energy

Compact overview of services

| Compatible materials | Polypropylene (PP, PP-GF), thermoplastic elastomers (TPE), polyamides (PA, PA-GF), plastics with and without filler materials |

|---|---|

| Mold size | 96x96 mm to 1396x1396 mm |

| Tool weight | Up to 10 t |

| Closing force | 20 t to 1700 t |

| Tools | Multi-component tools, valve gate tools, turntable tools, transfer tools, hybrid tools, hot-gas welding tools, prototype and series-production vibration welding tools, ultrasound welding jigs, ultrasound welding tools |

| Manufacturing technologies | CNC milling, die-sink EDM, start-hole drilling, deep-hole drilling up to a diameter of 50 mm, wire cutting, hard milling, high-speed milling, simultaneous milling, flat grinding, plate machining, polishing work, milling of electrodes out of graphite and copper |

| Assembly work | Ultrasonic welding of plastics, vibration welding of plastics, manual or automated component group assembly |

| Certificates | ISO 14001, IATF 16949, ISO 50001, ISO 9001, DIN ISO 45001, TISAX, AEO, Energy Efficiency and German Sustainability Code |

Send us a non-binding request now and we will advise you!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Flexible tool design and optimisation

Customers in all industries profit from our expertise and extensive experience in tool design. The individual requirements on molds vary depending on the sector of industry and the order. Our qualified staff precisely address your needs in order to deliver the ideal tool. Upon request, we realise, for example, injection-molding tools with hydraulic functions, multi-cavity molds or molds with hot-runner technology including needle shut-off.

Here are a few examples from our mold construction service portfolio:

Here are a few examples from our mold construction service portfolio:

- Injection-molding tools for cable guides

- Injection-molding tools for cable brackets

- Injection-molding tools for air ducts

- Injection-molding tools for covers

- Injection-molding tools for brackets

- Injection-molding tools for panels

- Injection-molding tools for structural components

- Injection-molding tools for intake manifolds

- Injection-molding tools for cylinder head covers

- Injection-molding tools for housings for thermal control units (oil management units)

- Injection-molding tools for dehumidifiers

- Injection-molding tools for air filters

- Injection-molding tools for expansion tanks

- Molding around inserts (bushings, strainers, fleece, fabric)

- Filter housings

- Air flap systems

- Cylinder head covers

- Engine compartment parts

- Bottom panels

- Small fixtures in general

Tool design: Full service for maximum customer satisfaction

LANGER is your tool design specialist with all-round service. We consider ourselves to be not only a service provider, we would also like to provide you with comprehensive support during your project. With our broad service portfolio, we are ready to help you with every stage of your work. From the idea to the finished tool, we are the ideal partner for every industry and every project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency and on-time delivery are just a few examples of the qualities that distinguish us as a reliable partner. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency and on-time delivery are just a few examples of the qualities that distinguish us as a reliable partner. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Have we aroused your interest?

Arrange an appointment for a non-binding consultation now!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Arrange an appointment for a non-binding consultation now!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)