Injection-molded engine components

From non-return valves to oil separators

LANGER is your partner for the manufacture of high-quality plastic engine components for every requirement. Besides manufacturing, we offer bespoke services for our customers in the fields of process solutions, design, assembly and tool construction. In the process, we draw on 51 years’ experience gained during our company's history. By means of virtual manufacturing simulation and automated quality control, we achieve a zero-error rate in the manufacture of engine components. Our customers all around the world profit from our high quality and sustainability standards.

- Design, mold construction, injection molding and assembly from a single source

- Large selection of plastics including two-component injection molding

- International logistics service and global delivery

Precise engine components from LANGER

You profit from our injection-molded parts for industry and the automotive sector

Plastic injection-molded parts are tailored to the customer’s needs, robust and inexpensive at the same time. To manufacture them, molten plastic is injected in a controlled manner into a mold, compacted and then interlinked and cooled. In this way, both simple and highly complex shapes can be realised in a wide variety of sizes. Short cycle times and low material costs make this process exceedingly economical.

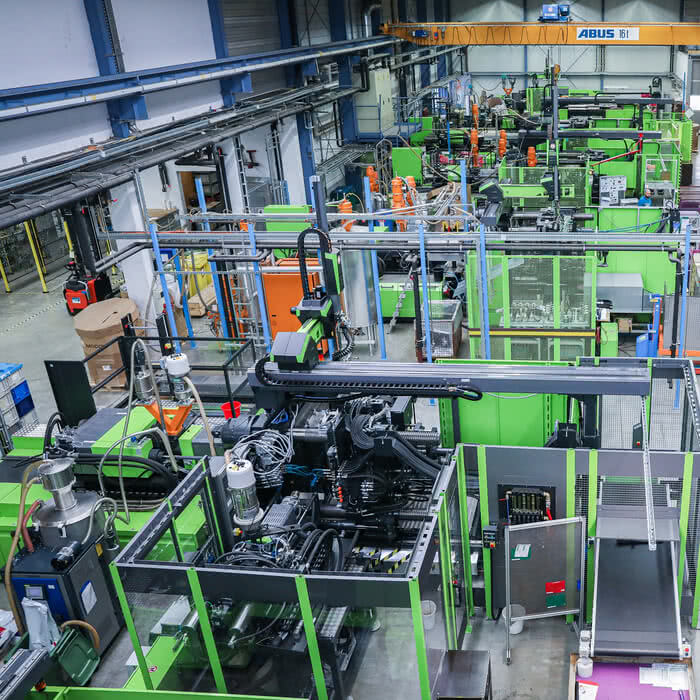

Using state-of-the-art machines, we manufacture engine components and add-on components for industrial engines precisely to your specifications. We specialise in the manufacture of molded parts in small batches or high-volume production. Our core competencies also include the manufacture of customer-specific tools and molds as well as design and assembly. From simple injection-molded parts to complex component groups, we find the ideal solution for every order.

Using state-of-the-art machines, we manufacture engine components and add-on components for industrial engines precisely to your specifications. We specialise in the manufacture of molded parts in small batches or high-volume production. Our core competencies also include the manufacture of customer-specific tools and molds as well as design and assembly. From simple injection-molded parts to complex component groups, we find the ideal solution for every order.

Send us a non-binding request now and we will advise you!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Managing Director

Head of injection molding department

Markus Beierl

+49 7558 930-604

Send E-Mail

Download VCard (.vcf)

Head of injection molding department

Markus Beierl

+49 7558 930-604

Send E-Mail

Download VCard (.vcf)

Flexible manufacturing from a single source

Profit during your project from our comprehensive services and our 51 years’ experience gained during our company's history. Short decision-making paths, customer-oriented production control, 24-hour production and express service make us an extremely flexible partner in your parts production. Numerous satisfied customers are a testament to our pronounced customer orientation. Among others, we receive orders from the automotive, construction, medical technology, mechanical engineering and electrical engineering industries.

From consultancy to quality control, you receive all services from a single source. In the process, the communication via EDI enables simple and flexible data exchange with our customers.

From consultancy to quality control, you receive all services from a single source. In the process, the communication via EDI enables simple and flexible data exchange with our customers.

You also profit from our expertise in injection molding and mold construction in these fields:

Prototype tool construction

Series-production tool construction

Cubing model construction

Inspection tool and gauge manufacturing

Renewable energy

Prototype tool construction

Series-production tool construction

Cubing model construction

Inspection tool and gauge manufacturing

Renewable energy

Uncompromising quality in the manufacture of customer-specific parts

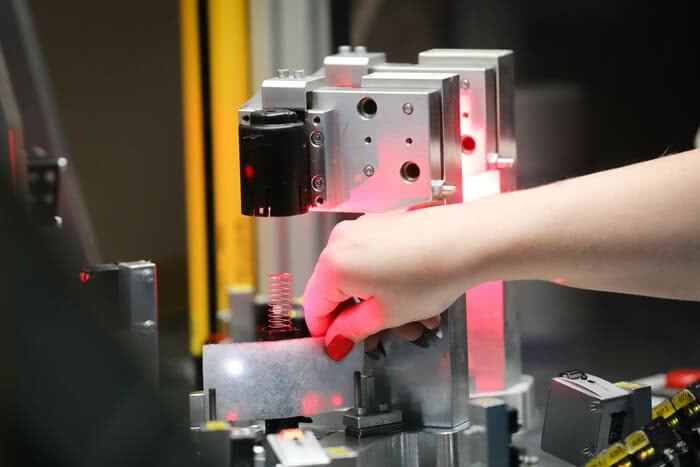

We implement your wishes in plastics engineering precisely down to the last detail. Our precision parts precisely meet your specifications within a hundredth of a millimetre. Automated quality control and sample inspection according to PPAP or PPF guarantee the consistently high quality of our products.

We offer a wide range of different high-performance thermoplastics, with and without glass fibre reinforcement. Our portfolio includes single- and multi-component injection molding. Certain colours can be added without problem upon request. We offer bespoke packaging, a transport service as well as storage of components.

Exemplary sustainability: Injection molding with responsibility

We set great store by environmentally friendliness during all process steps. We carry out single- and two-component injection molding in an extremely sustainable and resource-conserving process. We minimise the amount of waste material and recycle a huge amount of plastic. Furthermore, we offer reusable packaging for finished plastic parts.

Compact overview of services

| Injection-molding plastics | Polypropylene (PP), thermoplastic elastomers (TPE), polyamides (PA6, PA6.6), polybutylene terephthalate (PBT), polycarbonates (PC), acrylonitrile butadiene styrene (ABS) |

|---|---|

| Workpiece size | 15 mm to 1200 mm |

| Workpiece weight | up to 3 kg |

| Components | Hard components, soft components, single-component and multi-component injection molding, two-colour injection molding |

| Closing force | 50 t to 1700 t |

| Assembly work | Vibration welding, spin welding, ultrasonic welding, hot-gas welding, bonding |

| Tools | Multi-component tools, RTM tools, SMC tools |

| Certificates | ISO 14001, IATF 16949, ISO 50001, ISO 9001, DIN ISO 45001, TISAX, AEO, Energy Efficiency and German Sustainability Code |

Advantages of injection molding at a glance

Nowadays, it is impossible to imagine modern industry without the injection-molding process for engines components. It is with good reason that it is the most commonly used process for automated production of molded parts made of plastic. From check valves to crankcase breathers to oil sumps, we support our customers with high-quality precision components.

The advantages of injection molding at a glance:

The advantages of injection molding at a glance:

- Precise reproducibility: If a large number of identical parts are required, injection molding is the ideal manufacturing process. It guarantees absolute precision no matter how many parts are produced. This makes it an exceedingly reliable method for the manufacture of precise parts.

- Hardly any rework required: Parts made of plastic require little to no rework after removal from the mold. This saves the customer time and costs.

- High level of economic efficiency: It is possible to produce almost any number of copies of a part with a single mold. The greater the quantity, the lower the costs of each item. Series production using plastic injection molding is thus an exceedingly cost-saving process.

What injection-molding methods are available?

During the manufacture of parts made of plastic, one generally differentiates between duroplasts, thermoplastics and elastomers. The most important injection-molding materials from an economic point of view are thermoplastics. Although the different materials differ significantly with regard to their properties, in principle they are all brought into their desired form in the same way by means of injection molding.

We at LANGER work with conventional technical thermoplasts, high-performance thermoplastics and thermoplastic elastomers. We have the most suitable material in stock to suit every customer requirement.

We at LANGER work with conventional technical thermoplasts, high-performance thermoplastics and thermoplastic elastomers. We have the most suitable material in stock to suit every customer requirement.

Your project is in good hands with the LANGER GROUP

✔ Pre-engineering

Before the actual manufacturing, we contribute our huge repertoire of know-how and experience to your project.

Before the actual manufacturing, we contribute our huge repertoire of know-how and experience to your project.

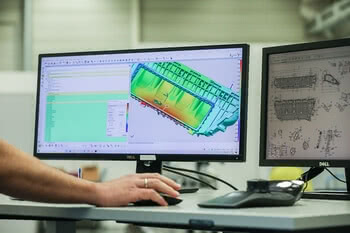

✔ Virtual simulation

We avoid rejects and waste material and save time and costs by digitally testing the injection process beforehand.

We avoid rejects and waste material and save time and costs by digitally testing the injection process beforehand.

✔ Automation

Thanks to a high degree of automation, we manufacture high-quality parts in large quantities on a daily basis.

Thanks to a high degree of automation, we manufacture high-quality parts in large quantities on a daily basis.

✔ Global delivery

We offer quality "made in Germany” and that all around the world. We would also be happy to deliver plastic injection-molded parts to your country.

We offer quality "made in Germany” and that all around the world. We would also be happy to deliver plastic injection-molded parts to your country.

Overview: How is a project conducted at LANGER?

As a full-service partner, we are ready to support you during every step of your project. A qualified contact person is available to help you at all times. This is how a project is conducted at LANGER:

Pre-engineering

Our specialists contribute their consultancy skills to your order right from the start. Qualified staff from different departments work together to find the perfect solution to cater for your needs. In this way, you profit from our wealth of experience and know-how during every phase of your project.

Design and development

We would be happy to take on responsibility for the planning, further development or the complete design of your parts. To this purpose, tell us what your parts are required for and which properties they should have. If you already have a draft design, we would be happy to help with its further optimisation.

Virtual simulation

A key component of our budget-oriented and efficient way of working is the virtual simulation of the parts production. Using state-of-the-art technology, we simulate and thus verify the manufacturing processes in a realistic virtual environment. Besides verifying the feasibility, this also enables optimisation and cost-saving potential to be discovered. The amount of waste is reduced to a minimum and thus also the cost of the project thanks to virtual simulation.

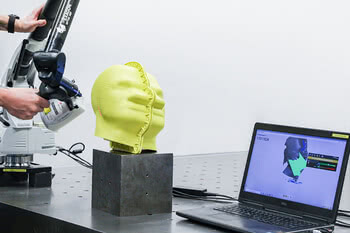

Tool construction

We manufacture finished injection-molding tools in a wide range of shapes and sizes and find the ideal solution for every order. State-of-the-art quality control measures and experienced employees guarantee the consistently high quality of our series-production tools, multi-component tools and prototype tools using computer tomography, laser scanning as well as optical and tactile measurement methods.

Parts production

Our core competency lies in the economical manufacture of precise plastic parts. The manufacture of your precision parts is automated to a large extent. Whether separator vessel, air filter box or cylinder head cover: Your expectations with regard to the finished product are put into practice with perfect dimensional accuracy. Material pre-drying is standard at LANGER. We use state-of-the-art technology and equipment to achieve maximum efficiency and cost-effectiveness. The digitalised production planning and the corresponding MES system are a huge advantage here for LANGER.

Quality control

At LANGER nothing is left to chance. After all, the key factors for engine components are absolute precision and close tolerances. Our automated quality control process thus ensures that your components precisely meet your expectations. If necessary, we also perform tightness tests. Meticulous measurement equipment management guarantees the reliability of all control processes. The documentation is digitally archived using a CAQ system.

Further processing

Injection-molded parts are often ready for further use directly after cooling and require no rework. However, if the customer would like us to, we are happy to perform further processing steps such as cleaning-up and demolding.

Logistics service

We deliver all around the world and are familiar with the challenges that can arise with international shipments. For this reason, we offer our customers comprehensive storage and logistics solutions including customs clearance and a transport service. In the process, we pay attention to continuous article traceability. We would be happy to enter individual agreements with regard to our customers’ post-series and spare-parts supply.

The best solution for every requirement: A wide range of custom engine components

Engines are made up of a multitude of different parts. Although their shapes and purposes vary greatly, they all have in common that their manufacture requires absolute precision. From LANGER you receive every type of plastic engine component exactly according to you wishes and specifications. The most commonly required engine components include the following:

- Non-return valves: Non-return valves and swing check valves are used in engines to prevent the return flow of condensate. Swing check valves and non-return valves allow flow in only one direction.

- Oil separators: When the engine is running, combustion gases are constantly fed into the oil circuit. To avoid overpressure, the gases are conducted into the engine’s intake tract. Separation devices such as oil separators and petrol separators prevent the oil being sucked off. Oil separator manufacturers set great store by particularly precise dimensions to ensure that the valves function efficiently.

- Oil filter module: The oil filter module sits in the oil filter housing and removes contaminants from the oil flowing from the oil sump. The filter components in the machine’s or the vehicle’s filter housing keep the oil circuit constantly clean.

- Intake manifold: In the engine the intake manifold has the task of routing the air into the combustion chamber in order to achieve uniform combustion. The air is cleaned beforehand in the air filter housing. Depending on the engine, water filter housings are sometimes required.

- Cylinder head cover: A cylinder head cover closes off the top of the engine and ensures that no oil escapes.

- Distributor cap: The purpose of the engine’s distributor cap is to distribute the ignition voltage from the ignition coil over the individual cylinders.

- Plastic cover: Most engines have a plastic cover, either angular or round, that mainly protects against noise and dirt. In addition, engine covers protect cables against damage caused by martens.

- Crankcase breather: A crankcase breather regulates the pressure in the engine crankcase. In addition, it is responsible for the removal of blow-by gases.

- Coolant expansion tank: Coolant that expands when it is heated up is collected in the expansion tank. As soon as the engine stops running, the coolant contracts again. The coolant expansion tank prevents underpressure occurring and thus also unwanted contraction of hoses.

List of plastic injection-molding machines | Excerpt

Engel Duo 5160H/860L/650 Combi with handling (two-component, rotary table, change-over unit)

Quantity: 1

Closing force: 6500 kN

Quantity: 1

Closing force: 6500 kN

Engel Victory 1060/200 tech with handling

Quantity: 1

Closing force: 2000 kN

Quantity: 1

Closing force: 2000 kN

Engel Victory 650/120 tech with handling

Quantity: 1

Closing force: 1200 kN

Quantity: 1

Closing force: 1200 kN

Engel Victory 200/50 tech.

Quantity: 1

Closing force: 50 kN

Quantity: 1

Closing force: 50 kN

Quality "made in Germany": Full service for maximum customer satisfaction

LANGER is your injection-molding partner with all-round service. We consider ourselves to be not only a service provider, we would also like to provide you with comprehensive support during your project. With our broad service portfolio that goes far beyond just injection molding, we are ready to help you with every stage of your work. From the idea to the finished part, we are the ideal partner for every industry and every project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency, top quality and on-time delivery are just a few examples of the qualities that distinguish us as an injection-molding manufacturer. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency, top quality and on-time delivery are just a few examples of the qualities that distinguish us as an injection-molding manufacturer. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Have we aroused your interest?

Arrange an appointment for a non-binding consultation now!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Arrange an appointment for a non-binding consultation now!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)