Custom welding tools

Welding fixtures for your requirements

LANGER is your competent partner with all-round service for the manufacture of welding tools. Customers from all industrial sectors profit from our services in custom tool development. We manufacture welding tools in a wide range of shapes and sizes and find the ideal solution for every order.

Our high-quality welding tools are suitable for all plastic welding processes:

Our high-quality welding tools are suitable for all plastic welding processes:

- Vibration welding

- Spin welding

- Ultrasonic welding

- Hot-gas welding

Tool holders: LANGER at a glance

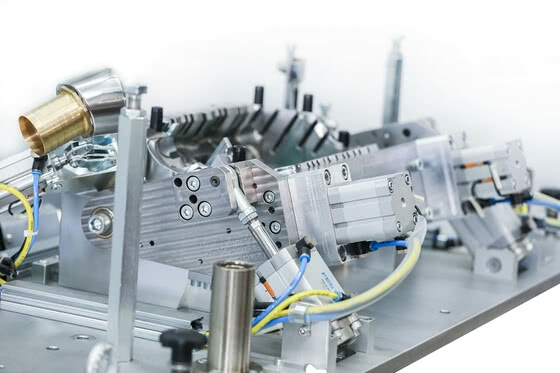

During the design of welding tool holders, we draw on 51 years’ experience gained during our company's history. We ensure the consistently high quality of our products using laser scanning as well as optical and tactile measurement. We deliver to customers all around the world and pay heed to a resource-conserving and sustainable way of working during mold construction.

This is why custom tool holders from LANGER convince our customers

Welding is a challenging manufacturing process that requires the highest degree of precision. Hence, high-quality welding tools and part holders are essential for clean results. They enable parts to be exactly oriented, supported, fixed in place and welded with the necessary accuracy. We support our customers with custom welding tool holders that are exactly tailored to the conditions of the parts to be welded.

From simple to highly complex shapes/contours, we provide you with custom holding tools in wide-ranging sizes. Our competencies also include the manufacture and assembly of component groups.

From simple to highly complex shapes/contours, we provide you with custom holding tools in wide-ranging sizes. Our competencies also include the manufacture and assembly of component groups.

Send us a non-binding request now and we will advise you!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Flexible manufacturing from a single source

As an all-round service provider in injection molding and mold construction, we want to cater for your wishes quickly and directly. LANGER thus excels due to short decision-making paths, customer-oriented production control, 24-hour production and express service. Numerous satisfied customers bear witness to our high degree of customer orientation.

From consultancy to quality control, you receive all services from a single source. In the process, the communication via EDI enables simple and flexible data exchange with our customers.

From consultancy to quality control, you receive all services from a single source. In the process, the communication via EDI enables simple and flexible data exchange with our customers.

Customers in the following fields also profit from our high quality standards:

Plastic injection molding

Cubing model construction

Inspection tool and gauge manufacturing

Renewable energy

Plastic injection molding

Cubing model construction

Inspection tool and gauge manufacturing

Renewable energy

Uncompromising quality in tool construction

We implement your wishes for custom welding tools precisely down to the last detail. State-of-the-art quality control measures and experienced staff ensure the consistently high quality of our products. Our all-round service includes bespoke packaging, an international transport service as well as storage of components.

Exemplary sustainability: Responsible manufacturing

We set great store by environmentally friendliness during all process steps. Our tool holder manufacturing is extremely sustainable and resource-conserving. We minimise the amount of waste material and recycle where possible. Furthermore, we offer reusable packaging for finished products.

Compact overview of services

| Welding tools for: | Ultrasonic welding of plastics, vibration welding of plastics, rotation welding of plastics, hot gas welding of plastics |

|---|---|

| Certificates | ISO 14001, IATF 16949, ISO 50001, ISO 9001, DIN ISO 45001, TISAX, AEO, Energy Efficiency and German Sustainability Code |

Different welding processes at a glance

In many industrial sectors, the welding of plastics plays an important role. Depending on the requirements, various different methods are available for this. We adapt our customer-specific welding tool holders to suit your needs so that you always achieve clean and high-quality results when welding.

Vibration welding

During vibration welding a part moves against another stationary part at high frequency. The frictional heat produced by this ensures precise, clearly defined molten material at the weld. For this process the parts must be matched up perfectly in the joint zone for the weld. Vibration welding is particularly suitable when welding together non-uniform, complex or large plastic parts.

Spin welding

To connect two plastic parts by means of spin welding, these are pressed together at the dividing seam and one of the parts is spun quickly. This produces frictional heat that ensures that the parts melt into each other precisely at the desired position. Various factors, for example the welding seam geometry, friction speed and welding pressure, determine the strength of the resulting weld. Due to the way it works, spin welding is only suitable for round welds.

Ultrasonic welding

As the name suggests, bundled ultrasonic waves are used during ultrasonic welding in order to melt and join plastic parts. The vibrations are transferred into each part by means of sonotrodes, which are then joined by applying additional mechanical pressure. The targeted bundling of the ultrasonic waves can occur either through the tool geometry or the structure of the part itself.

Hot-gas welding

During hot-gas welding, plastic parts are melted to the welding filler on both sides by means of hot gas and subsequently joined together, i.e. welded. Unlike the use of other, mechanical methods, no microparticles are produced during hot-gas welding. Many plastics that are considered to be difficult to weld can be welded without problem by means of hot-gas welding. Hot-gas welding produces a particularly homogeneous and hard weld.

Your project is in good hands with the LANGER GROUP

✔ Pre-engineering

Before the actual manufacturing, we contribute our huge repertoire of know-how and experience to your project.

Before the actual manufacturing, we contribute our huge repertoire of know-how and experience to your project.

✔ Virtual simulation

We avoid rejects and waste material and save time and costs by digitally testing the injection process beforehand.

We avoid rejects and waste material and save time and costs by digitally testing the injection process beforehand.

✔ Automation

Thanks to a high degree of automation, we manufacture high-quality parts in large quantities on a daily basis.

Thanks to a high degree of automation, we manufacture high-quality parts in large quantities on a daily basis.

✔ Global delivery

We offer quality "made in Germany” and that all around the world. We would also be happy to deliver plastic injection-molded parts to your country.

We offer quality "made in Germany” and that all around the world. We would also be happy to deliver plastic injection-molded parts to your country.

How is a project conducted at LANGER?

As a full-service partner, we are ready to support you during every step of your project. A qualified contact person is available to help you at all times. This is how a project is conducted at LANGER:

Consultancy/pre-engineering

Our specialists contribute their skills to your order right from the start. Qualified staff from different departments work together to find the perfect solution to cater for your needs. In this way, you profit from our wealth of experience and know-how during every phase of your project.

Design and development

We assume responsibility for the complete planning and design of your welding tools. Tell us what requirements apply to your parts and exactly what their are required for. If you already have a draft design, we would be happy to help with its further optimisation.

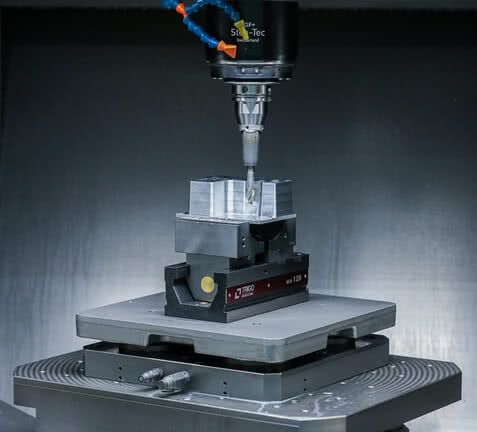

Production

One of our core competencies is the manufacture of high-quality welding tools. Your expectations with regard to the finished product are put into practice with absolute precision. For maximum efficiency and cost effectiveness, we use our certified in-house production.

Quality control

When you commission LANGER to manufacture fixtures, nothing is left to chance. After all, the key factors in this field are absolute precision and close tolerances. Our in-house quality control includes laser scanning, optical and tactile measurement, 3D measurement, 3D coordinate measurement as well as initial sample test reports. The evaluation is carried out using the software Polyworks. We create measurement reports according to the drawing or the measuring plan. Meticulous measurement equipment management guarantees the reliability of all control processes.

Logistics service

We deliver all around the world and are familiar with the challenges that can arise with international shipments. For this reason, we offer our customers comprehensive storage and logistics solutions including customs clearance and a transport service. In the process, we pay attention to continuous article traceability. We would be happy to enter individual agreements with regard to our customers’ post-series and spare-parts supply.

Welding tools "made in Germany": Full service for maximum customer satisfaction

LANGER is your specialist for welding tools with all-round service. We consider ourselves to be not only a service provider, we would also like to provide you with comprehensive support during your project. With our broad service portfolio, we are ready to help you with every stage of your work. From the idea to the finished tool, we are the ideal partner for every industry and every project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency and on-time delivery are just a few examples of the qualities that distinguish us as a reliable partner. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Let us convince you, too, through our customer-oriented way of working. Close cooperation with our customers, transparency and on-time delivery are just a few examples of the qualities that distinguish us as a reliable partner. Our qualified employees welcome every new challenge and would be happy to also find the ideal solution for your project.

Have we aroused your interest?

Arrange an appointment for a non-binding consultation now!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)

Arrange an appointment for a non-binding consultation now!

Sales of prototype and series tools, injection moulded parts

Reinhold Wesselak

+49 7558 930-806

Send E-Mail

Download VCard (.vcf)